Today’s photovoltaic (PV) industry must rely on licensed structural engineers’ various interpretations of building codes and standards to design PV mounting systems that will withstand wind-induced loads. Previously this had been a problem because although permitting agencies do require assessments of the structural attachment of solar equipment to rooftops, the safety, and sufficiency of these attachments are not adequately addressed in any codes or standards. The result was a multitude of code interpretations from a range of individuals and groups, that often yielded different design loads for the same design specifications.

However, with the introduction of ASCE 7-16, that is all changing. For the first time, an ASCE Code specifically addresses rooftop solar and the new version of ASCE 7 provides 2 methods for calculating the proper wind load. With hurricane-force winds becoming ever more prevalent, wind load calculations are increasingly valuable knowledge for contractors and engineers to have, particularly in the southeast of the US.

Solar America Board for Codes and Standards Recommendation

- At present, they recommend basing the structural design of roof-mounted PV systems on the ASCE Standard 7-16 as follows:

- Main wind-force resisting system (MWFRS), is the recommended starting point for designing the PV mounting structure, with the PV module oriented above and parallel to the roof surface.

- Sections 29.4.3 and 29.4.4 address updates on wind loads on solar panels for low sloped roofs (7 degrees or lower) and the second update is for panels that are installed parallel or close to parallel to the roof. Greentech Renewables' in-house engineering team would recommend the use of figures 29.4-7 and figures 30.3-2 through 30.3-7 in determining the proper design wind pressure and the correct external pressure coefficient.

- The Solar America Board for Codes and Standards recommends wind tunnel testing be conducted for the most common rooftop PV installations to verify methods and calculations. The installation types include standoff mounting parallel to the roof, stand-off mounting at an incline relative to the roof, and ballasted installations on flat roofs.

- They recommend that codes and standards be modified to specifically address the mounting of PV arrays to rooftops to eliminate potential barriers to market development in high wind regions.

The formula that ASCE 7-16 uses for wind pressure solar design is as follows:

Wind Pressure = Velocity Pressure * external pressure coefficients * yE * yA

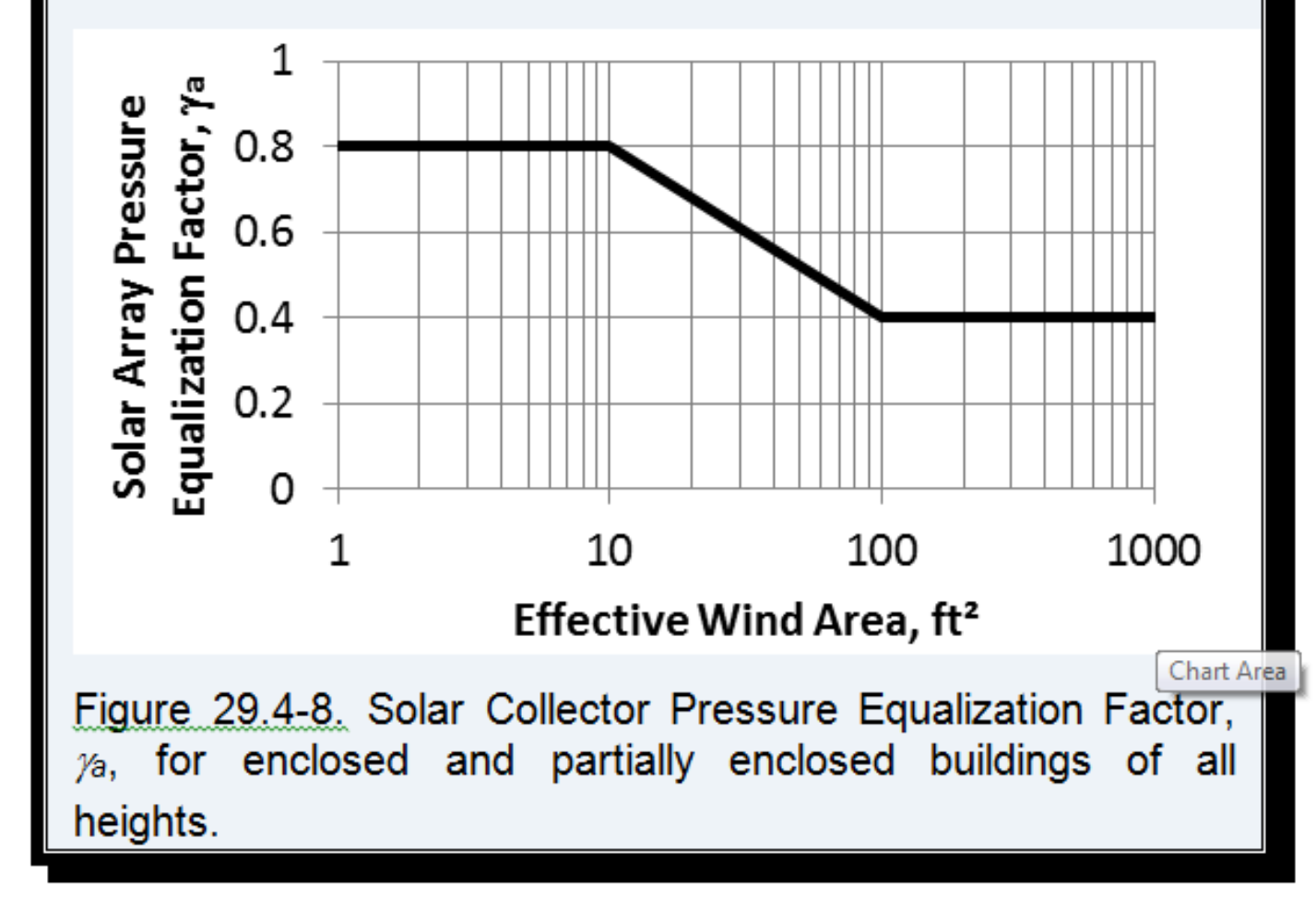

The external pressure coefficients are based on the components and the cladding of roofs, it can be calculated based on figures 30.3-2 through 30.3-7 or 30.5-1. yE is a coefficient that will either be 1 or 1.5 depending on whether the panels are exposed to the roof edge. If they are exposed, 1.5 is used, if the panels are not exposed,1 is used in the equation. yA is another coefficient called the equalization factor. Figure 29.4-8 of ASCE shows the range of values for yA, essentially running from .4 to .8 depending on the effective wind area (effective wind area is calculated by Height * Height/3). For yA, if the wind area is between 1-10 ft squared then yA equals .8, if the effective wind area is greater than 100 ft squared yA will be .4. The yA between those two points can be seen in the graph below. Using the 4 parts of the equation together then you can calculate the wind load for an array.

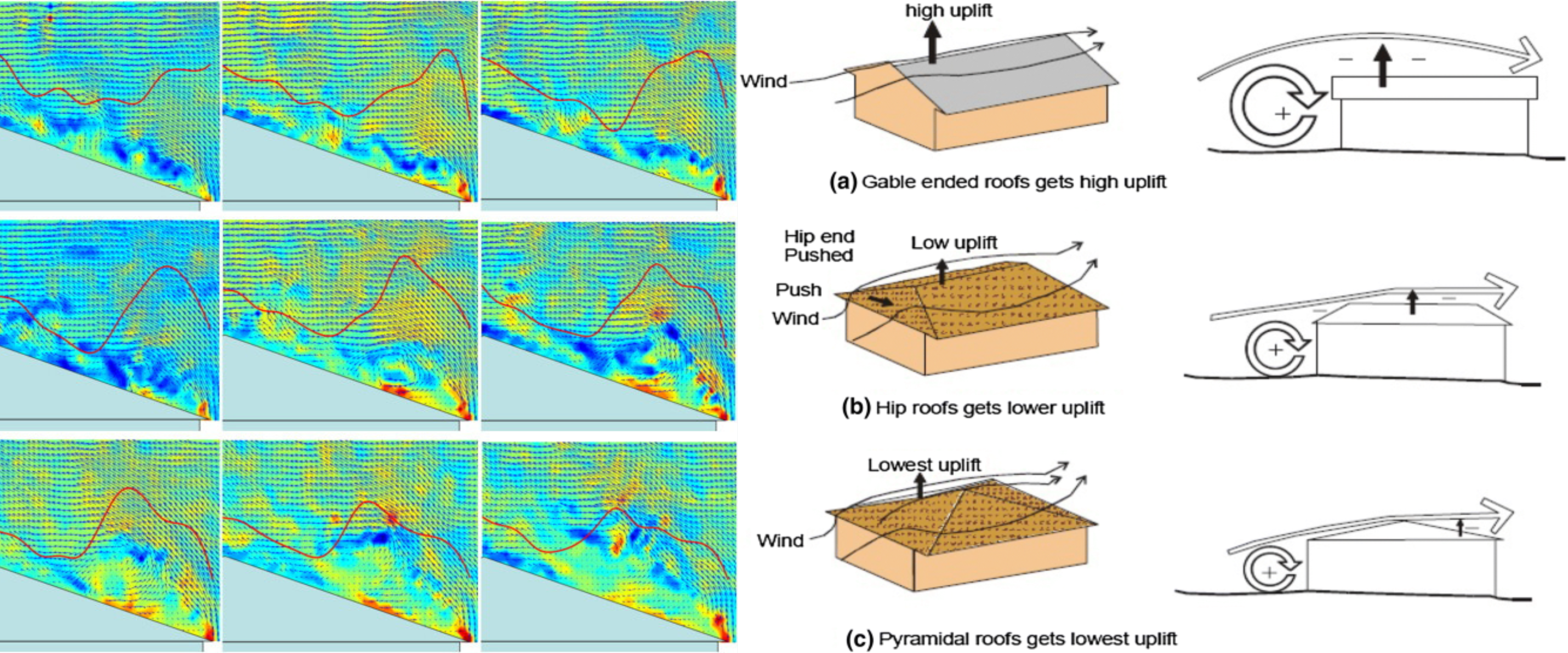

Right: Rooftop Wind Comparisons

ASCE 7 has also provided this helpful tool that allows you to test any location in the US, and find out the wind, rain, snow, flood, earthquake, ice, and tsunami risk factor. If you have additional questions about wind loading and the requirements for your next project, reach out to your sales rep today to learn more!

Comments

Thanks for this article. One of my customers is telling me that he wants the stand offs for his solar installatoin on his roof to be 18" high so that he can crawl under the panels if he needs to work on his roof. Here is a photo of his roof. Any thoughts on why doing such a high stand off is a good or bad idea? I am concerned about both the wind loading and the strain on the roof mountings. Thanks for the thoughts on this issue.

If it's seamed metal roof, S-5! clamps (you can use the PV-Kit) are recommended. They can withstand high uplift loads as they can grip on the seams.

I don't quite understand why he would like to crawl under the modules. But he can use Unirac Solarmount Low Profile Tilt Legs that would allow him to lift one end of the array even up to 44".

In this case wind exposure could be an issue which needs to be calculated. He will need a structural engineer to figure it out if he is at a windy site (exposure C and D).

Actually for this type of roof the S-5! will not work. It is hard to tell from this photo, but there is nothing for the S-5! clamp to attach to. We actually suggest using the Chemlink Solar Shoe. Greentech Renewables offers the Solar Shoe but it is not yet in the online catalog. If you Contact Greentech Renewables for pricing and availability they will get right back to you.

That is a thru-fastened metal roof (i.e., 5V-crimp type) on that building. These are not structural panels as most stanting seam roofing is. Raising the structure 18" above the roof will most likely increase the forces on the racking system. You shouldn't attach the solar to the roof membrane. It would be best to get to the structural framing under the roof for attachment. The building engineer should let you know what loads can be added to the existing design. In many cases, the underlying roof purlins may not be able to support the loads either and you may need to attach to the main building columns and span roof penetrations. It is advisible to also include the roofing company in any penetration work to maintain any performance warranties on the roof membrane.

Here is an array in my area that has somehow survived many years as a sail!