In this week’s article I am reviewing Unirac’s recent advancements in their SolarMount racking products.

In an ever growing racking market, with all of the options that are out there, it can be overwhelming to determine which features actually help save on installation time as well as over-all material cost. Let's look at Unirac SolarMount.

Arguably one of the most costly and time consuming tasks is how a system is electrically bonded. We all are familiar with the vast varieties of the module and rail lugs, bonding jumper or straps, and the bare wire that is used to successfully bond a PV system. Those little bits and bobs really do add up. Not to forget the time and effort that goes into installing them all. Unirac’s response to that comes in the form of some very intuitive and well designed products.

You may recount using the old mid and end clamps. You probably pre-assemble them on the ground and put them in your tool bag to make installing them on the roof a little easier. Those days are behind us. The new mid and end clamps come pre-assembled for you. The clamps, nuts and bolts are kept together with a washer. These washers have another benefit in that they stay in place on the rail until everything is ready to be tightened down. No longer does one need to hassle with grabbing another clamp to replace another when it tumbles out of place and slides down the roof.

Both the end and mid clamps now come with bonding teeth the bite into the module frames and the SolarMount rail. No need for lugs anymore or bare copper wire to make the bond between each of these modules.

Another notable upgrade to the mid clamps is that they are now made of stainless steel. The width has also changed. Formerly, the mid clamps created a one inch gap between each of the modules. Now they push the module frames together down to a mere quarter of an inch. This makes for a much more aesthetic look to the array. This also lends to having the ability to squeeze more modules in a given roof area with the tighter grouping.

With the new bonding splice offered by Unirac, no longer is it necessary to have any bonding straps or jumpers between rail segments. The new splices come with serrated teeth that form a complete bond by biting into the rails.

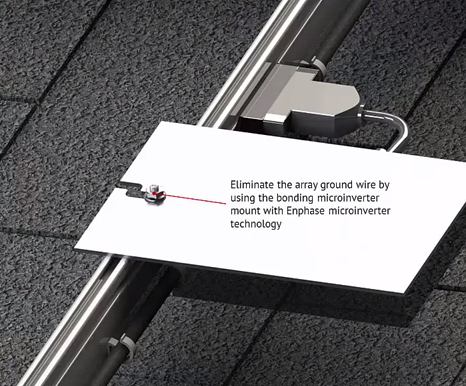

If the system includes the new Enphase micro-inverters with integrated bonding (models ending in “IG”), the need to have a bare copper wire on the roof is eliminated completely. I know that would have a lot of installers very excited to hear. Not only does this eliminate a lot of time spent running the bare copper bond, but it eliminates a large expense too. Also, Unirac has larger wire clips that are compatible with the Enphase branch cable to help speed up the time taken for wire management.

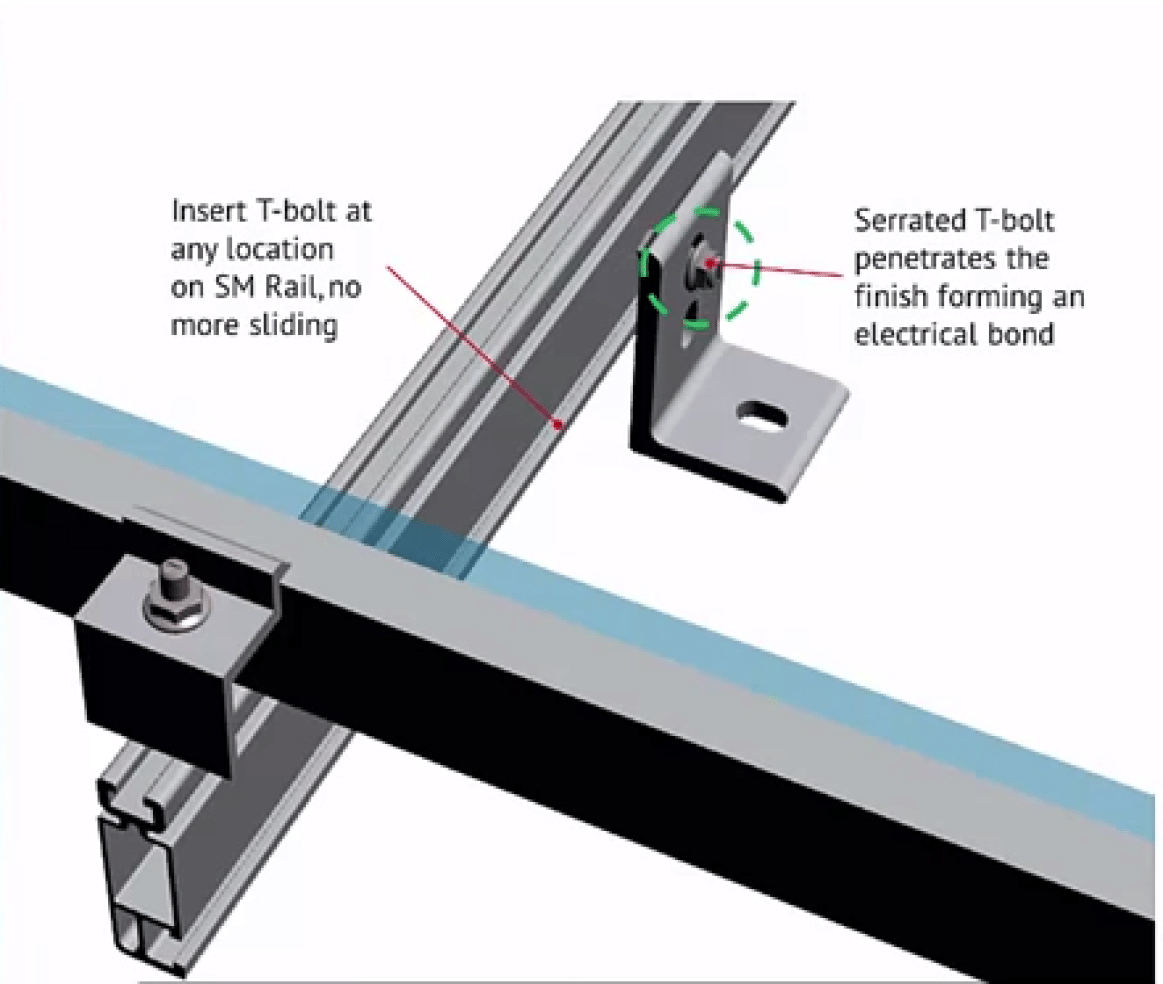

Now I saved the best for last. Do you despise needing to slide those old hex bolts into the rail so that you can attach them to the L-feet? Don’t you love how the bolts would snag or get stuck easily? That’s hard on your back. Or better yet, you slid one too many between a rail splice and discovered this after it’s all been tightened down. What a pain…. But no longer! Now, the L-feet come with T-bolts, making it far simpler, if not a joy, to insert into the rail and tighten them to the L-feet. Of course, these also bond the L-feet to the rails like the clamps and splices do.

Overall, I have to say that these new advancements in the SolarMount hardware make for a much more pleasurable installation than what we have all dealt with in the past. Who doesn’t want to get off the roof quicker… and save some dough in the process?

If you haven’t already, take a look at these beauties below.