So, you’ve invested in your dream PV system. It’s been months since you signed the contract with your installer and there have been a couple of rocky times in between then and now. None of that matters now because the day has finally come when the switch gets flipped to the ‘ON’ position.

Your installer completes the commissioning checklist, does a quick walkthrough of the system with you, provides you with a user manual and then, flips a couple of switches and leaves the final AC disconnect flip for you to operate. You pinch the arm on the outside of the disconnect and begin to move it in the upwards position. As you do so, you think to yourself, “Wow, this switch doesn’t move very smoothly.” As the arm moves past the horizontal position, it snaps upwards with a noticeable noise. The system is on. Phew.

As you wait for the inverter to complete its startup phase you think about all of the energy the system is supposed to produce. You review the production estimate reports that were prepared months ago and start imagining lower electric bills. The inverter completes the startup procedure and begins to export power. You watch the inverter display cycle through various system conditions such as the array voltage, current and power. It’s so exciting to finally have your own power production system and it’s all from solar. To confirm operation, you walk over to the analog production meter that you’ll become very familiar with to see the dial spin. If it’s spinning, you’re producing power.

A few months pass by. The electric bills are lower and you’re about to report the system’s monthly production for SREC purposes. This is an exciting time because you know that the system will finally reach 1MWh which means your first SREC is just around the corner. You head downstairs with phone in hand and the website loaded, ready for logging the monthly production. When you reach the meter, you notice that the system did not reach 1MWh. It came up short by a little over 150kWh. “What?” You run over to the inverter to view the display. The information seems correct, but you really aren’t sure if it is. Attempting to understand the system you start to hastily review the system’s user manual. Unfortunately, most of the information is foreign to you. Although you know something is wrong, you just do not understand enough to troubleshoot the system so you call your installer.

You leave a message for your installer because he wasn’t available at the time you called. That evening, you receive a return phone call from the installer. You both discuss what has happened. Your installer says that the earliest he can have someone stop by is in about three days. You respond, “but my system isn’t producing the energy that you said it would.” This was not the best comment because there are many reasons why the system didn’t reach the expected production target. Your installer responds that it would be easier to troubleshoot if monitoring was in place. Unfortunately, when you signed the contract the monitoring options didn’t seem worthwhile at the moment. Here’s the first sign that monitoring would have been a good idea.

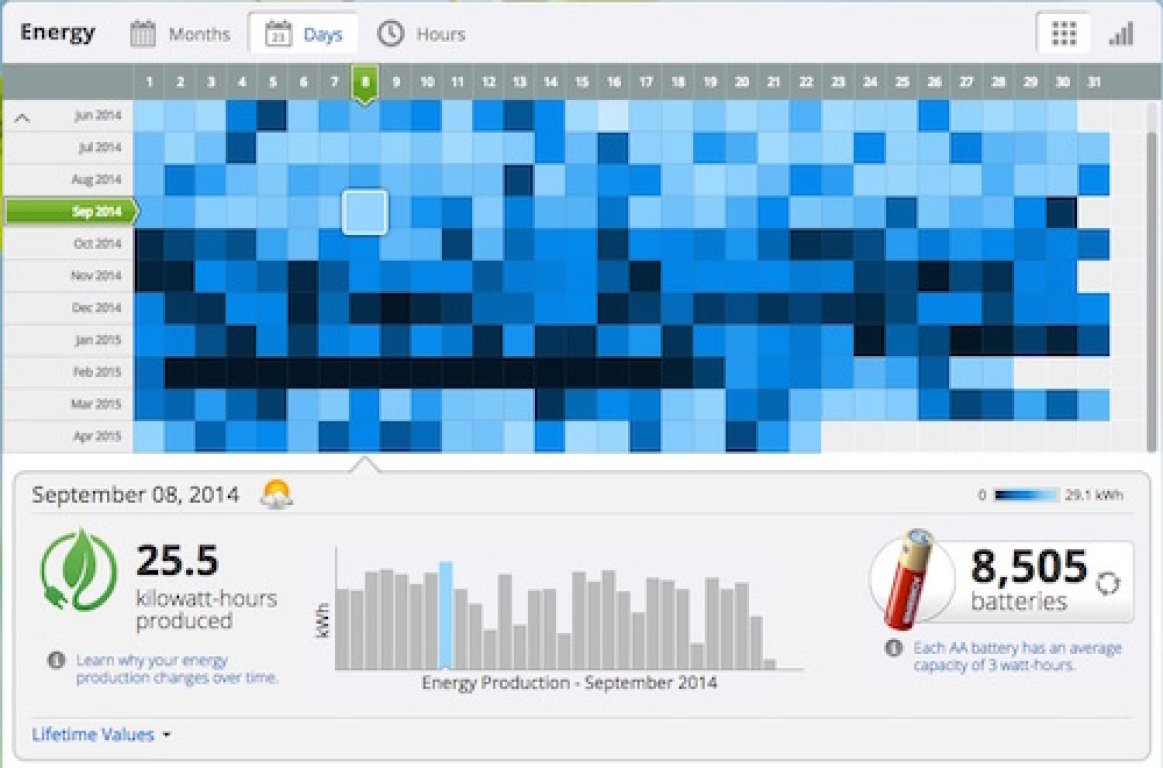

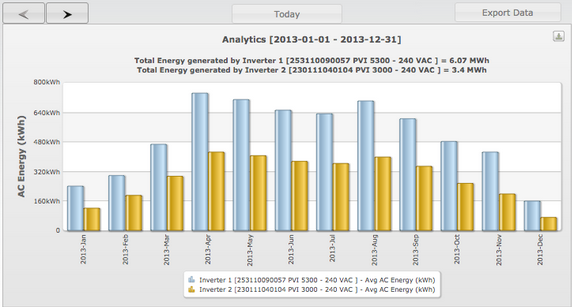

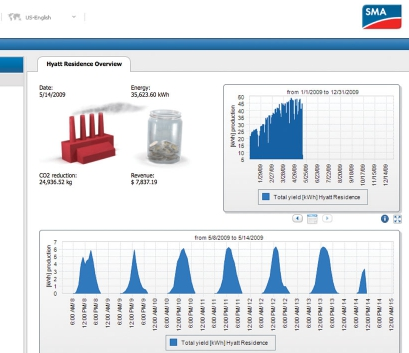

PV systems and monitoring go hand in hand. There is no better way to quickly check the health of your PV system than to utilize a remote monitoring system. A monitoring system allows the system owner to verify that their investment is operating as expected. It also helps the system owner to further understand how the system functions, acting as a learning tool. For the installer, a monitoring system provides insight into a system for remote troubleshooting. It also serves as excellent marketing and learning tools.

Monitoring systems are available in a variety of capabilities ranging from extremely simple to extraordinarily complex. For residential PV systems, simple monitoring systems usually suffice for verification and troubleshooting needs. These systems have built-in and sometimes user-programmable alerts that notify the system owner and installer if the alarm thresholds / setpoints are met at any given time. This allows both parties to quickly act to resolve any issues that might arise during the lifetime of the system.

In the example above, if a monitoring system was present it is likely that an alert would have gone out to both the system owner and installer notifying both parties that a production issue is present. Depending on when the event(s) occurred, the issue could have been resolved sooner. Additionally, prior to arriving on site, the installer would have an opportunity to review system data remotely, beginning the troubleshooting process.

In conclusion, for residential PV system owners, I highly suggest purchasing a monitoring system to accompany your PV system. For installers, I highly suggest including monitoring with all of your systems. This strategy will prove more than valuable as your business develops over the years.

Next time, we’ll discuss the different monitoring systems available and which ones are compatible with which inverter systems.