Residential PV system designs sometimes require installing modules in landscape orientation. Usually this is due to constraints with roof dimensions. Other times it can be due to aesthetic desires. In any case, landscape orientation can present some design challenges when it comes to racking. Although there are many solutions to these challenges there is a single product that solves almost every challenge and does so in a very appealing manner.

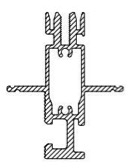

The product I speak of is Unirac’s SunFrame. The SunFrame rail is different than a majority of mounting rails wherein it utilizes two flanges that modules rest on and a cap strip to hold the modules in place against the flange. See Figure 1 below for a profile view of the rail.

Figure 1 : Profile of SunFrame Rail

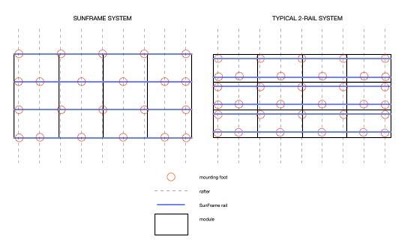

The SunFrame rail is installed horizontally along the roof, spanning the rafters. This allows for distributing the array load more evenly across the members making up the roof structure especially when the mounting feet are staggered between rails (see Figure 2).

Additionally, the SunFrame system uses less material when compared to a typical 2-rail per row configuration. The number of rails is reduced because one rail is shared between two rows. With the shared rail, the number of roof penetrations is greatly reduced as well. For example, the array layout in Figure 2 consists of three rows of four modules each. In a typical 2-rail per module row application, this array would require a total of six rails. Using SunFrame, this array only requires four rails. As for mounting feet, the 2-rail system would require thirty three whereas the SunFrame system would only require twenty two mounting feet. Further, when the 2-rail system is employed, an issue sometimes arises when mounting feet are directly above one another between two rows. When this occurs, the flashing kits can overlap making the installation more difficult to install as well as increasing the risk of water infiltration at the lower roof penetration.

Figure 2 : Example of Array Layout

Speaking of difficulty, Sunframe has its own set of small intricacies. When using SunFrame, all modules must be individually grounded instead of using grounding top-down clamps or WEEBS. Additionally, SunFrame requires some additional mounting plates or L-feet if the system will be utilizing micro-inverters or rail-mounted power optimizers. The savings in racking equipment and the final appearance of the SunFrame system are well worth having to add a couple of extra grounding lugs and / or micro-inverter mounting plates.

In summary, the SunFrame racking system from Unirac is a great solution when modules are installed in landscape orientation. SunFrame offers a fairly simple installation process, requires less material than the 2-rails per row system and provides one of the most aesthetically pleasing final products available on the market for residential rooftops. Consider using SunFrame the next time your PV array requires modules in the landscape orientation.

PS. SunFrame is available in an anodized finish for arrays requiring an all-black finish.