Integrated Grounding FAQ

-

Is UL 2703 a new standard?

UL 2703 is currently an Outline of Investigation, which means it has not yet been accepted by ANSI as a standard. However, while the acceptance process is underway, products can still be listed to the outline, and it's just as valid as a listing to an established standard.

-

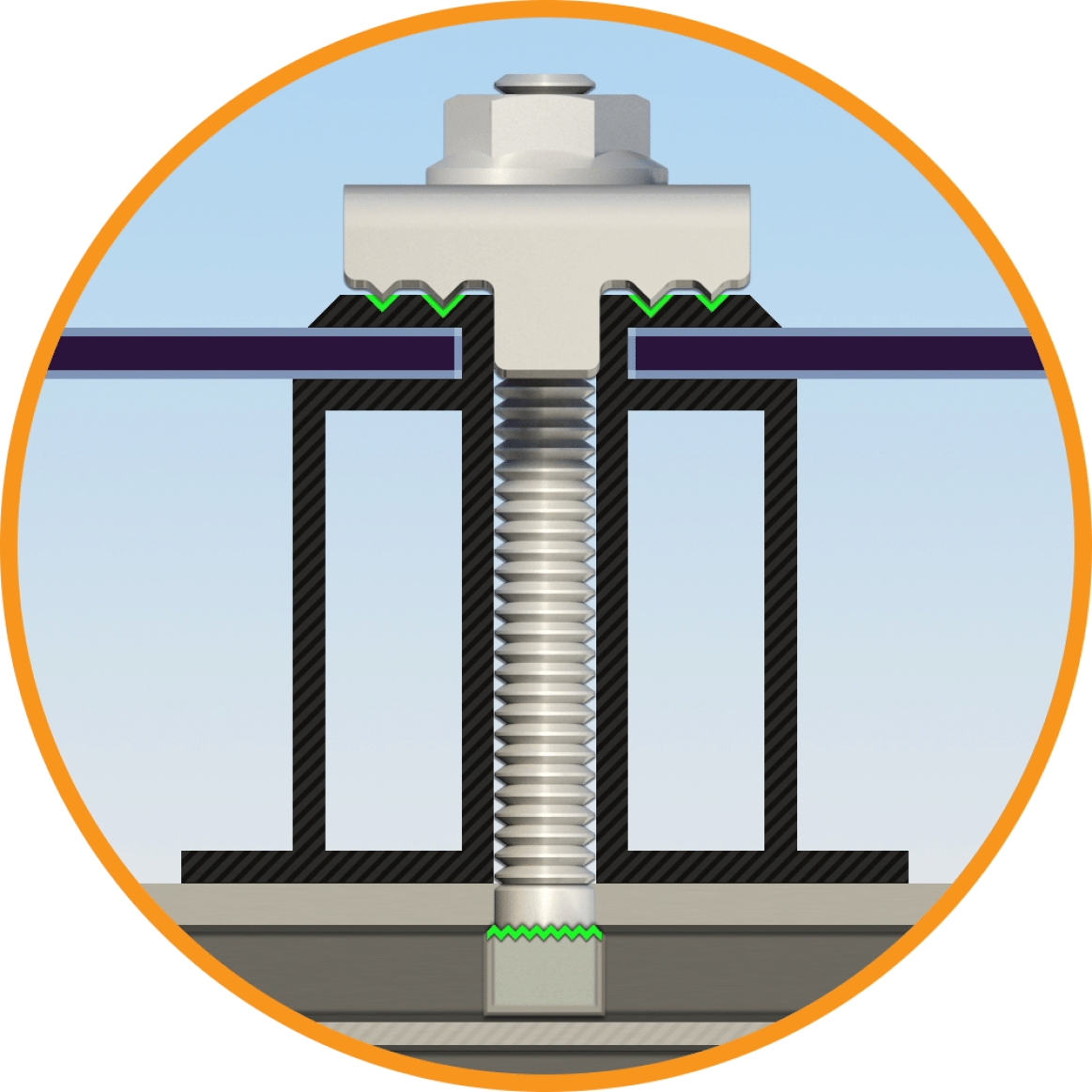

How is the grounding different from WEEBs?The IronRidge listing covers both the modules and the rails. This means that the module frames and rails are considered an electrically continuous system, requiring fewer jumpers and lugs.

-

How many times can the clamp be loosened and re-tightened on the module?The Grounding Mid Clamp has been tested and certified to re-tighten a minimum of ten times.

-

Can an outdoor-rated bonding jumper be used instead of an IronRidge Grounding Strap?Alternative bonding jumpers are not included within the UL 2703 listing. Use of these products may cause concern with the Authority Having Jurisdiction (AHJ), and could lead to a failed inspection.

-

Does the module manufacturer need to list IronRidge as a grounding means in their installation manual?The UL 2703 certification process includes extensive testing of the IronRidge components with the module. These tests are identical to the tests performed in the module listing process (UL 1703). As a result, the UL 2703 listing covers both products, not just the mounting components.

-

Will it void the module warranty if the IronRidge clamp is not listed in the module's manual?The IronRidge System does not harm the module, but you should always confirm warranty questions with the manufacturer before installing.

-

Will piercing the module anodization cause corrosion in coastal environments?The UL 2703 certification process included extensive environmental and corrosion testing. The high quality stainless steel used in the IronRidge Grounding Mid Clamps does not cause significant galvanic corrosion, even in extreme environments.

-

Can microinverters or power optimizers be used with the Integrated Grounding System?The UL 2703 listing does not cover microinverters or power optimizers, but it may be possible to ground these devices to IronRidge rails. You must ensure the grounding method complies with the documentation provided by the manufacturer.

FlashFoot FAQ

What is the warranty of the product?The FlashFoot has a 20 year warranty. And, like all IronRidge products, the FlashFoot’s expected useful life is greater than 30 years.

Will it preserve the roof’s warranty?The FlashFoot is designed to work with all standard composition shingle roofs. However, you must review the roof manufacturer’s warranty information to ensure compliance. As well, you should contact the original roofer and work with them to preserve the labor warranty on the roof.

What is the minimum roof slope to use FlashFoot?The FlashFoot is designed for steep slope roofs, and should only be installed on roofs with a 3:12 pitch or greater. This equates to approximately 14 degrees of slope.

Is the product certified?FlashFoot is certified for compliance with the 2006 & 2009 International Building Codes (IBC) & International Residential Codes (IRC).

What is IAPMO-ES?IAPMO-ES prepared the Evaluation Report for FlashFoot. IAPMO-ES is an ANSI accredited provider of building product certification services per ISO/IEC 17065, making it capable of certifying products as compliant with multiple building codes.

How was FlashFoot tested?FlashFoot was tested for structural and waterproofing performance. Mechanical testing conformed to the standard for Testing and Analysis of Joist Hangers and Miscellaneous Connectors (EC002-2011), and rain testing conformed to the Underwriters Laboratory Standard for Gas Vents (UL 441-96 Section 25).

Why does the Load Distribution Plate stick out from the bottom?The Load Distribution Plate sits “proud” of the flashing layer by approximately 1/8” because this improves the FlashFoot’s ability to adapt to thicker shingle types and protect against deflection or deformation during installation.

Can the mounting rail pull out of the open-top L-Foot?No. If the attachment hardware is properly tightened, there is more than enough friction to prevent slipping. In addition, there is a lip on the top of the L-Foot to prevent loose hardware from slipping out.