If you missed Part 1 of our racking series you can catch up HERE.

Rails:

The IronRidge XR Series is available in the following lengths: 11’, 14’, and 17’.

This array has an E/W length of 32.7’.

32.7’ / 11’ = 2.97pcs of XR 11’ rail

32.7’ / 14’ = 2.34pcs of XR 14’ rail

32.7’ / 17’ = 1.92pcs of XR 17’ rail

In this case, we would go with EITHER (3) 11’ rails OR (2) 17’ rails. We would avoid using the 14’ rail because that would require 3pcs of 14’ but more than half of one rail per row would be cut off by the installer as excess and thus wasted. Further, because the 17’ option requires only one splice per length of rail while the 11’ option requires two splices, we would generally recommend the 17’ option to reduce the labor/materials cost of the attendant splices. (However, you might want to spec in the 11’ rail for other reasons. For example. it may be possible to ship the 11’ rails via ground while the 17’ rails would always require a freight shipment.)

Note that each row of panels requires two lengths of rail, so this particular array would require (4) XR 17’ rails.

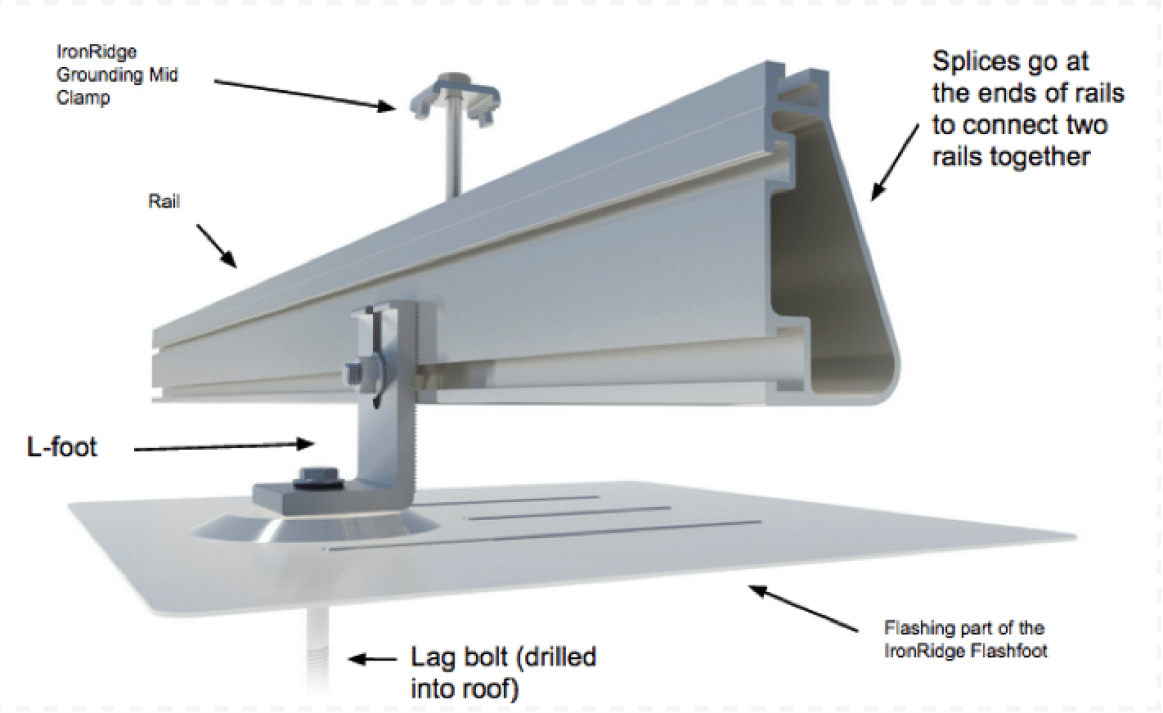

Splices:

This array would require two splices, one for each length of rail. Note that splices are specific to the rail type (ie XR10s use a different splice than XR100s, which use a different splice than XR1000s)

Mid clamps:

[(number of panels in each row) - 1] x 2

In this example, this would be:

[10 - 1] x 2 = 18

18 mid clamps are needed

End Clamps:

(number of rows) x 4

In this example, this would be:

1 x 4 = 4

4 end clamps are needed

L-feet:

Refer to the max spans for the IronRidge XR Series here.

For this array, assume a snow load of 20psf and a wind load of 140mph (always err on the side of too conservative when spec’ing racking). These values give us a max span for the XR10 of 4’.

32.7’ / 4’ = 8.175 l-feet per rail length

To be conservative, round up and add at least one extra l-foot per row.

8.175pcs > 9pcs + 1pcs = 10 l-feet per rail length

There are 2 rail lengths in this array which gives us a total needed l-foot quantity of 20pcs

Wire clips:

Some installers prefer to use heavy duty UV-rated zip ties, but others prefer the wire clips supplied by IronRidge. If IronRidge wire clips are used, a conservative estimate would be 2 wire clips per panel. There are 10 panels in this array which gives us a total needed wire clip quantity of 20pcs.

End caps:

End caps are generally for aesthetic appeal and are not absolutely mandatory. If end caps are desired, you’ll need two end caps for every rail length. There are two rail lengths in this array which gives us a total needed quantity of four end caps. Note that end caps are specific to the rail type (ie XR10s use a different end cap than XR100s, which use a different end cap than XR1000s).

The total racking BOM for this array comes to:

(4) XR10 17’ rails

(2) XR10 splices

(18) mid clamps

(4) end clamps

(20) l-feet

(20) wire clips

(4) end caps

Location of Racking Components (1x10 Portrait Array with Rails E/W):

Note: for the purposes of the diagram, the rail is depicted above the panels. In actual

applications, the rails are located below the panels