Ground-mounted solar arrays are a compelling alternative to traditional roof-based systems. Unlike rooftop arrays, ground mounts offer flexibility in achieving a more ideal array tilt and avoid shingle roof lifespan concerns.

There are two basic types of foundation geometries, single post and double post. Single post foundations are those where a single row of foundations support the racking structure. The single row of posts are aligned along the length of the array towards the center to rear ¾ of the front-to-rear array dimension. Various racking configurations are available to install. The most common consists of cantilevered struts and braces making up the strongback which resembles a "number four" in profile. Module rails are installed spanning the strongbacks along the length of the array.

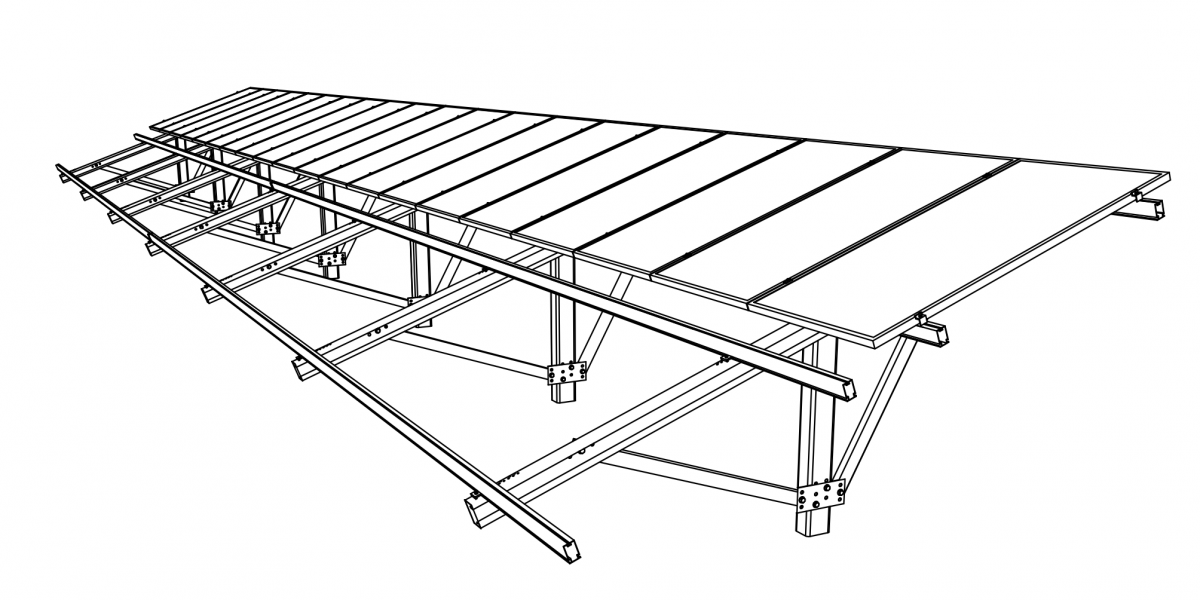

Double post foundations use two rows of foundations (one front and one rear) to support the racking structure. In this configuration, horizontal supports span the foundations for each of the rows creating the base where module rails are connected. Module rails will span the front and rear horizontal supports with slight cantilevers at each end. Depending on environmental and soil conditions bracing between each pair of front / rear, foundations could be required.

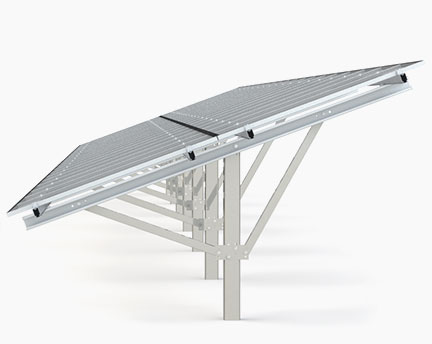

If space allows, single post ground mounts could be an ideal solution for both residential and commercial. In addition to the improved cantilever aesthetics, single-post ground mounts are designed with cost and install time in mind. Many of the largest arrays in the country employ this style of ground mount. Depending on soil conditions, piles can be quickly driven into the ground without the need to dig or pour foundations.

A standout among single post ground mounts is the Unirac Ground Fixed tilt or GFT. The GFT has evolved from more than 12 years of experience meeting a variety of project requirements. A combination of steel components and aluminum parts deliver performance while minimizing system cost. Installation savings are captured through efficiently engineered components, optional pre-assembled parts and integrated bonding for optimized construction sequencing.

Approved for use with a wide range of 60 and 72 cell modules in a 2-up portrait orientation (see a full list of approved modules on page 24), the GFT can be designed to accommodate tilts of 10 to 30 degrees. The GFT can also accommodate up to 10 degree East/West ground slope without modification. This is particularly useful at sites with uneven terrain that may otherwise require pre-installation leveling. From big to small, UL2703 integrated bonding and grounding mean less time spent fiddling with small parts to ensure NEC code compliance.

To aid with permitting, each Unirac GFT project receives standard drawings and calculations. The GFT is covered by a 20-year manufacturing warranty on all parts.

As always, one should be sure to keep inter-row spacing in mind to avoid your arrays shading one another and impacting energy harvest. For a detailed look at calculating how much space is required between each array see our article HERE.