The prospect of having a PV mounting support system without mounting rails is nothing new. Previously it involved having a racking support system that was integrated with a module's frame, such that it was interlocking. This required modules' manufacturers to develop frames for their modules that would be compatible with the racking system. As you can imagine, this posed problems for installers and module manufacturers.

To make them work, a module manufacturer would have to partner with the racking company and design a frame that would support the rail-free components of the racking manufacturer. This meant that the module manufacturer would have to custom design and stock compatible frames and then halt regular production in order to process distribution or large commercial orders that intended to utilize this type of frame and racking product. It does not require much imagination to deduce that this creates problems for module manufacturers. They had to invest in research and development of the frame work, warehouse the frames until they were needed, and invest time in shutting down normal production to switch over to the new frames to complete orders. For them this meant that rail-free frames had to be sold at a premium, which limited the number of manufacturers who would support making frames for this type of racking to merely a handful.

To an integrator, rail-free racking was great. Speedy installation, less materials and labor, and hopefully a lower installation cost that would be beneficial to the end-user. The problem was, that there were few module manufactures willing to make compatible frames for the racking which in turn limited the integrator and the end user to a few brands and modules of a specific output. For some, this was a huge deterrent.

Recently, Quick Mount PV came up with a racking solution that addresses these draw backs. They designed a racking system that would allow the use of most types of modules frames. These frames do not have to be custom designed by a module manufacturer to be compatible, thus eliminating the need for any R & D on the manufacturers' part or having to switch production between rail-free and standard frames. It also give the integrator and the end user their choice in module brand.

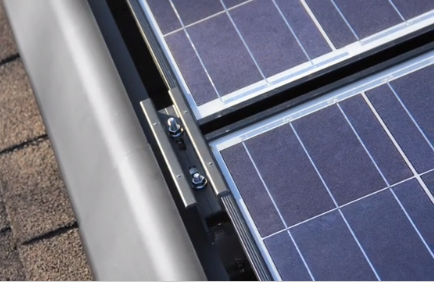

Quick Mount’s new system is called Quick Rack. It’s a very elegant and simple design that incorporates the flashing and weather proofing methods that they are known for with simple and aesthetic components to make for less complex installation and a clean looking finished product.

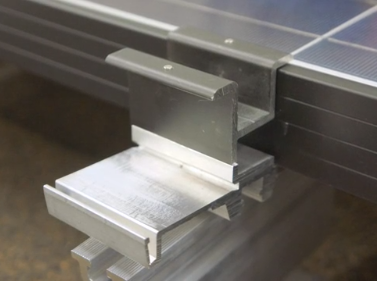

There are three basic components to the Quick Rack system. The base mount with flashing, panel clamp and array skirt. The base mount is affixed to the roof’s support members at spans according to their design table (included at the end of this article). This base has a rail slider which looks very similar to a standard rail attached to it but it’s only a few inches in length. The panel clamp is connected to the slider where the modules are affixed. The integrated grounding allows for up to 300 modules to be grounded to the same lug. This is a huge savings in hardware and ground wire for even the smallest arrays.

The optimal orientation would be to mount modules in landscape in order to take advantage of longer spans per the tables were in high velocity wind zones with the least amount of snow loading the maximum span could be a much as 72” and at the least 48”. In portrait mode in the same set of conditions the max span could be 48” with a minimum of 32”

The Quick Mount system for rail-free installations will quickly become the go-to for installers that would otherwise be confined to using modules with frames that are only compatible with one type of racking system. This new systems give them the greater freedom in system design coupled with the benefits of having less labor and material cost.