Grid-interoperability has been a main focus of the solar industry since it first emerged as a competitive option for generating energy. Extensive regulation over the grid, along with the widespread adoption of the NEC, have created a consistent set of standards for photovoltaic systems. As a result, all the inverters in the market today deliver high efficiency, easy installation, and MPPT technology, which work to maximize energy yield of solar panels. Recently, grid compatibility, simplified system design, and ease of installation have become the key differentiators for many solar contractors.

We're currently seeing a significant shift in the market from string inverters towards micro-inverters, module optimizers, and AC modules. Microinverters alone grew 180% in 2011 and an estimated 70% growth this year,1 because they can offer simplified design and easy installation, especially for those more familiar with the AC side of things. They also have unique benefits like lengthy warranties and per-module monitoring, reducing risk and enhancing O&M. Is this the AC-ification of the industry, on the way toward the holy grail of plug-in panels? Or are optimizers and maximizers the better solution?

Here's a brief comparison of the technologies and likely scenarios for their use:

String Inverters | DC-DC Optimizers | Microinverters | AC Modules |

| PROS - High efficiency (up to 98%) - Low unit cost per watt | PROS - Ability to step up or down each module’s voltage while optimizing total system yield output, - Module level communications and monitoring. | PROS - Efficiencies close to central inverters, - Module level communication and monitoring, - System design simplified. | PROS - Enables the module to generate a grid-compatible AC power, - Minimizes installation time and eliminates DC wiring, - System design reduced to simply planning AC circuits. - Have to offer at least 25 years of warranty conditions that would match the solar module warranty conditions. |

| CONS - Cannot respond to module mismatch, - Safety concerns over DC wiring, - Inability to monitor individual module performance, - Failure of the inverter will result in a complete system failure, - Design and site limitations, - Warranty conditions (have to be replaced at least once throughout the life-time of the system). | CONS - Dependent on central inverter, - Failure of the inverter will result in a complete system failure, although inverter failure is becoming increasingly rare, - Additional cost, but proven savings in BOS costs for certain sizes of systems | CONS - Additional cost, - Additional labor for installing each microinverter, - Warranties (have to be replaced at least once throughout the system’s lifetime) | CONS - Additional cost of equipment. |

String Inverters

Ideal project: Residential and Commercial roofs with no shading and relatively even thermal characteristics.

These units are the descendants of the off-grid inverters that were first certified to anti-islanding standards, giving up their batteries and pushing their power to the grid instead. The rule of thumb is that a string inverter is roughly equivalent to a combiner box in PV capacity. Anywhere between 700 and 30000 watts, string inverters can land all PV strings in one attached combiner and not require a sub-combiner.

The high initial cost of this architecture, which pushed development of central inverters for large scale projects, has fallen to the very low $.20/watt range, bringing attention back to string inverters of less than ~30kW. A weakness still remaining is that some types of electrical faults are hard to detect in the array.

Though they are the the cheapest option by installed watt, they have two major flaws:

- They see the solar array as one big PV module represented by the lowest common denominator in the array, and

- an electronic failure in the inverter can result in complete production loss.

These two weaknesses can be mitigated by employing string level monitoring and by separating high risk components into modular assemblies - the drawback, of course, is a bump in cost to add redundancies.

Power Optimizers

Most projects in the 10-500kW range where shading is at all likely - especially roofs in high temperature regions and roofs with a wide range of thermal zones.

DC-DC optimizers are useful when the performance of solar panels in a system vary widely due to power output differences, shading, azimuth or any other reason, by mitigating a disproportionate output reduction over the whole array due to the failure of a single module.

Optimizers maximize the energy yield of each solar panel by tuning the output to match the performance of the string inverter through MPPT. Using optimizers for each solar module in a solar system clearly increases the energy yield, but it also increases the total cost of the system because optimizers can only be used as an add-on to a solar inverter. This is changing as string inverters are being simplified to take advantage of the pre-conditioned DC power from the optimizer.

DC Optimizers are the technology most likely to become truly integrated into the module junction box first due to their lower complexity. We'll likely see substantial product developments in 2013 toward integrated optimization.

Microinverters

250W to 100kW systems with any shading issues or need for high resolution monitoring

A microinverter essentially combines an optimizer with a small inverter for every single (or every double) solar module. Microinverters have similar advantages to using optimizers, furthermore they reduce installation time significantly. Most of the microinverters on the market have additional monitoring features, thus enabling system owners to monitor the energy yield of each module instantly. Micros also reduce time and effort during troubleshooting.

The disadvantage of microinverters versus other technologies is the higher initial equipment cost per peak watt - and a relatively short track record.

AC Modules

250W to 10kW systems with any shading issues or requirement for high resolution monitoring. PV design and installation by any electrician - no DC familiarity is required at all.

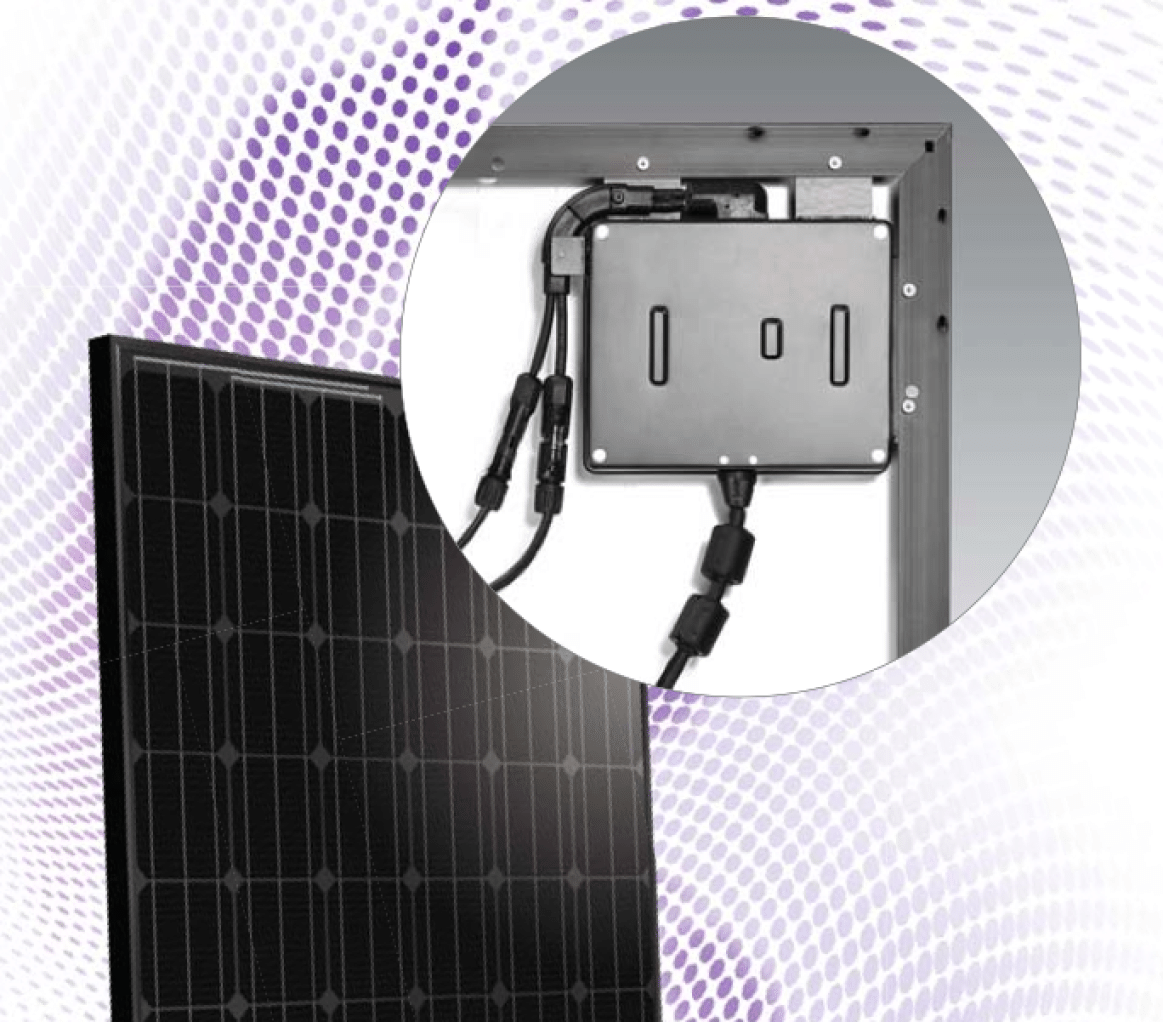

AC Modules are solar modules with integrated microinverters. The AC inverters mounted on the back side of the solar modules produces AC power without the need for DC connections in the field. AC modules carry all the advantages of using microinverters; the main disadvantage being the higher equipment cost per watt. Using AC modules can significantly simplify system design, permitting, installation, and maintenance.

Conclusion

What we think of as the evolution of the AC module, should probably be termed Evolution of the Smart Module. Logically, if the point of connection is an AC grid, then having AC power coming from the module makes sense - but there are still integration issues to address with micro inverters and in the case of commercial and larger systems. It may actually make more sense to monitor and precondition the power on the module, but then do the DC/AC conversion in a big, dumb, reliable string or central inverter. In either case, it's safe to say that a lot more intelligence will be moving into the module as these technologies develop.