This article will discuss the advantages of using microinverters with AC coupling for residential, single-phase applications. One of the leading microinverter manufacturers in the U.S. market is Enphase Energy. This microinverter manufacturer is headquartered in California and has pushed the envelope with AC coupling compatibility. For more information regarding the basics of AC coupling, see HERE for design considerations. If you’re interested in learning more broadly about retrofitting solar PV with battery backup, see HERE. This article covers the basics of adding energy storage with microinverters; moreover, it discusses the methods Enphase uses to communicate with battery inverters. Further, battery adoption will likely continue to accelerate as utilities impose more time-of-use rates, cap net metering interconnections, and add demand charges.

AC-Coupling with Microinverters

For homeowners interested in maximizing their production on a module-level and or those who would also like an energy storage system to take advantage of a TOU rate and/or backup power solution, AC-coupled storage systems with microinverters are a great option. In this type of system, microinverters are attached to the modules and the branch circuits or strings are combined at a gateway combiner box. They are then fed to a critical loads panel which is also connected to a battery inverter. This battery inverter is responsible for managing the flow of energy to the batteries while also mimicking the frequency of the grid in case of an outage to allow for continued PV production. Hence, when the grid goes down, the battery inverter uses an internal contactor to separate from the grid input and to isolate the critical loads panel from the grid. You can also configure the system to have an external ATS or contactor on the grid side of the main service panel (MSP) to power the main service panel directly. This could eliminate the need for a separate critical loads panel if the inverter(s) and battery are big enough to carry all the loads and surge loads on the MSP. An external ATS would be required when a customer is looking to power the main service panel; however, it does add extra cost and complexity.

One advantage of using Enphase in an AC coupled system is that microinverters allow for the flow of power to be divided between the backup system and the grid. Thus, the use of microinverters allows for flexibility in the size of storage capacity. For instance, some branch circuits can connect to the sub-panel that the battery inverter feeds while others can exclusively connect to the main panel. Even when some of the microinverters are connected to the battery, the entire array is eligible for net metering credits. However, if the grid goes down, the microinverters that are connected at the main panel will stop producing as they are isolated from the critical loads panel which is being fed by the battery inverter.

Currently, Enphase is brand agnostic towards storage inverters, but some work better than others. Installers can use any backup system that fits one’s budget, technical constraints and design preferences. With Enphase, the main feature to keep in mind is where the battery inverter can shift its frequency based on the state of charge of the battery bank. This allows the battery inverter to control the PV array output when in off-grid mode. Outback is a popular battery inverter that can’t frequency shift, but it can trigger a relay to knock the PV system offline, thus protecting the battery from overcharging. In this case, the PV system would shutter on and off based on the battery bank’s state of charge. Put differently, this scenario equates to trying to fill a cup by turning a firehose on and off. However, if a frequency-shifting inverter like Schneider is used, PV would be curtailed to match the loads that are currently on the panel, even if the batteries are at a full state of charge.

Power Curtailment Methods

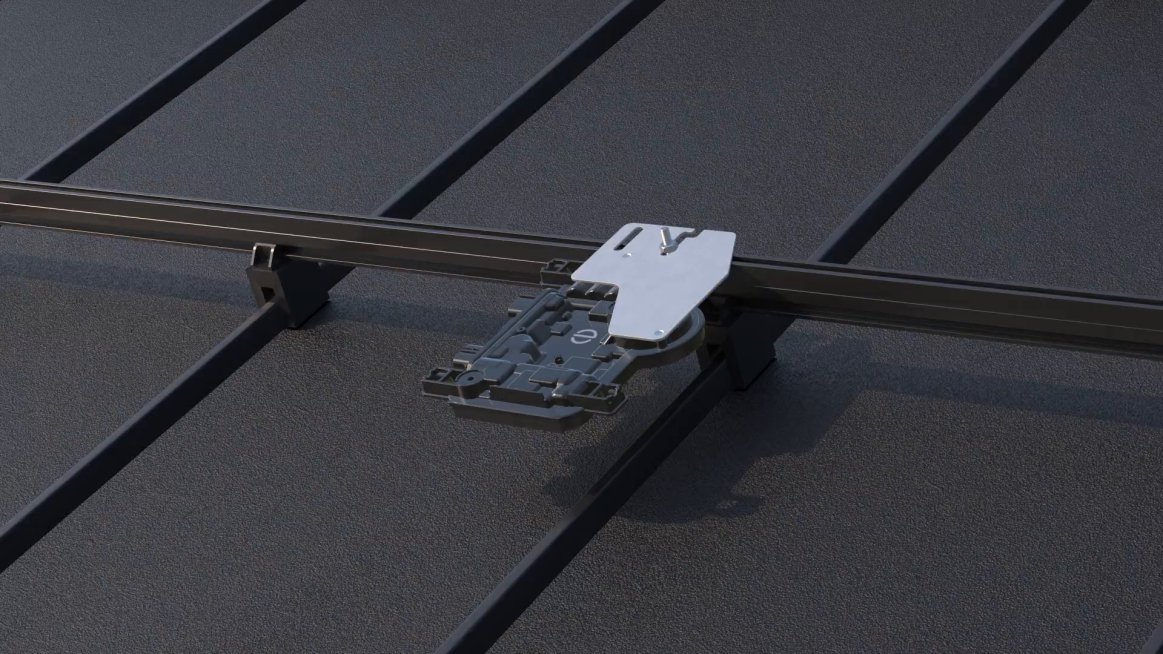

Enphase microinverters have the ability to accommodate a wide range of wattages. Most modules, 60-cell or 72-cell, will be compatible with the IQ7 or IQ7+. See the image below for a diagram of the AC Coupled layout:

Enphase power curtailment options include External Relay Control, AC Frequency/Trip, AC Frequency/Watt and Power Export Limiting.

External Relay Control measures voltage and can trigger a full or partial disconnect if need be. Depending on local interconnections, there may be a time delay in reconnection. This operation can lead to a shuttering of the system where the battery system sees all or none of the full power of the PV array depending on the battery’s state of charge. This is a relatively crude way to AC couple.

AC Frequency / Trip is an interconnection setting that sets an over-frequency trip threshold to halt microinverter production when the frequency reaches the pre-set threshold. This method should be used with older M215 and M250 models which don’t support gradual curtailment.

AC Frequency / Watt can gradually curtail power based on the AC frequency. The microinverters back off the maximum power point voltage thus reducing overall AC output. This feature is available with the IQ lineup of microinverters. Overall, it’s easier on the capacitors within the microinverter and the battery system to ramp the production up and down rather than trip it.

Enphase’s Power Export Limiting is for interconnected systems that require an export limit. To limit PV export, the system must be outfitted with consumption metering. It automatically sends power curtailment commands to the microinverters via the powerline communications. Data is pulled from the consumption meter every 500ms and makes adjustments to the microinverter output at 1.5-second intervals. The IQ Envoy adjusts every two to four seconds.

Enphase provides options to maximize the end customers’ return on investment. The right fit depends on the product mix, design preferences, and size of a system. For more information about retrofitting microinverter systems with storage or interest in AC coupled systems using microinverters, contact your Greentech Renewables Account Manager.